WE ARE A TRADITIONAL COMPANY SPECIALIZING IN

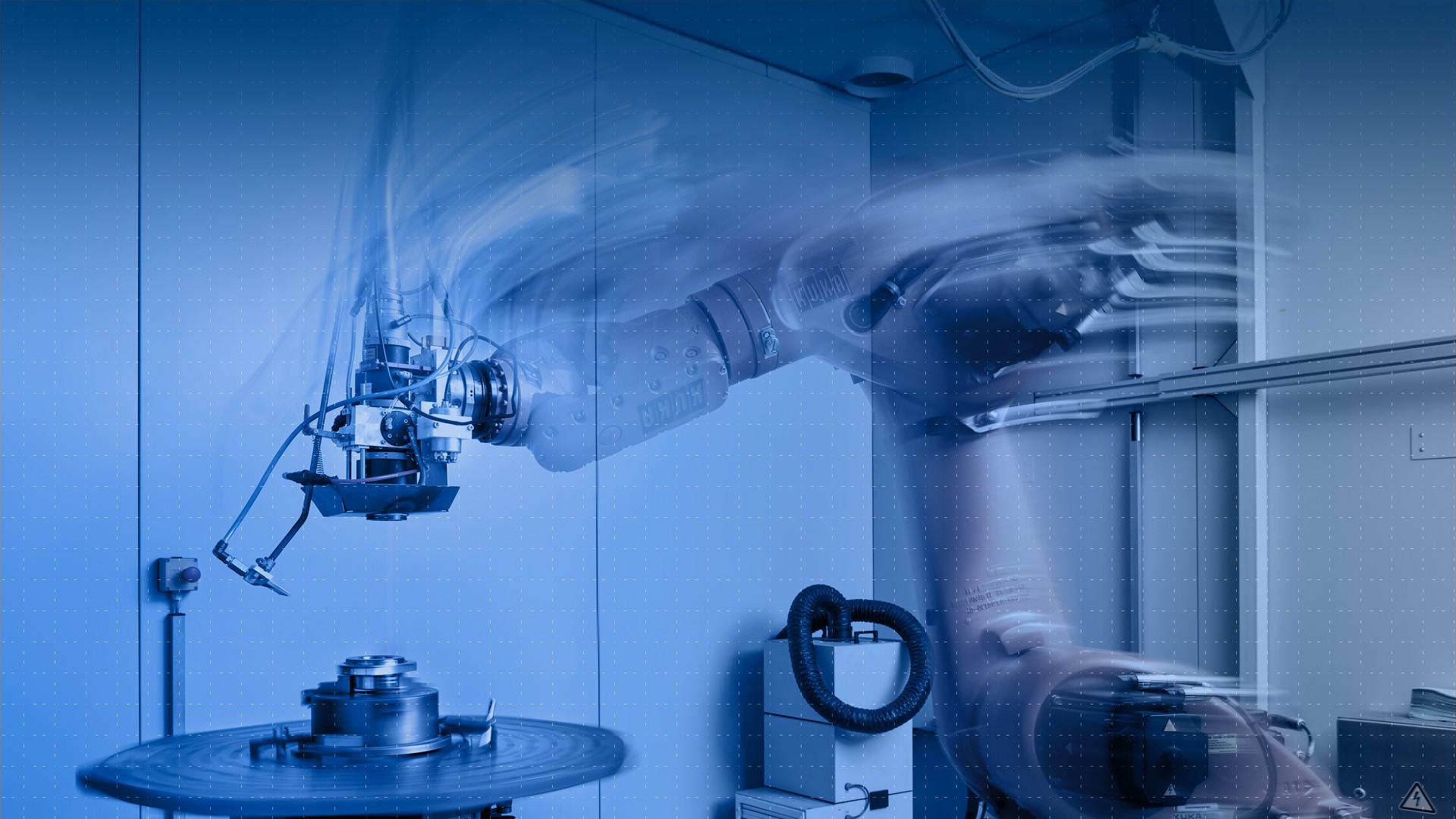

APPLIED RESEARCH AND DEVELOPMENT IN MECHANICAL ENGINEERING

We are unique

Many years of experience and our know-how are the basic building blocks of all that we do.

WE BRIDge SCIENCE AND INDUSTRY

We successfully transfer new technologies and methods to the industrial environment and offer innovative solutions.

HIGH PROFESSIONAL QUALIFICATIONS

We are one of the most modern research and development centres in the Czech Republic focused on the needs of industry.

Years of experience

Employees

Grant projects

Prototypes annually

Patents

Customers worldwide

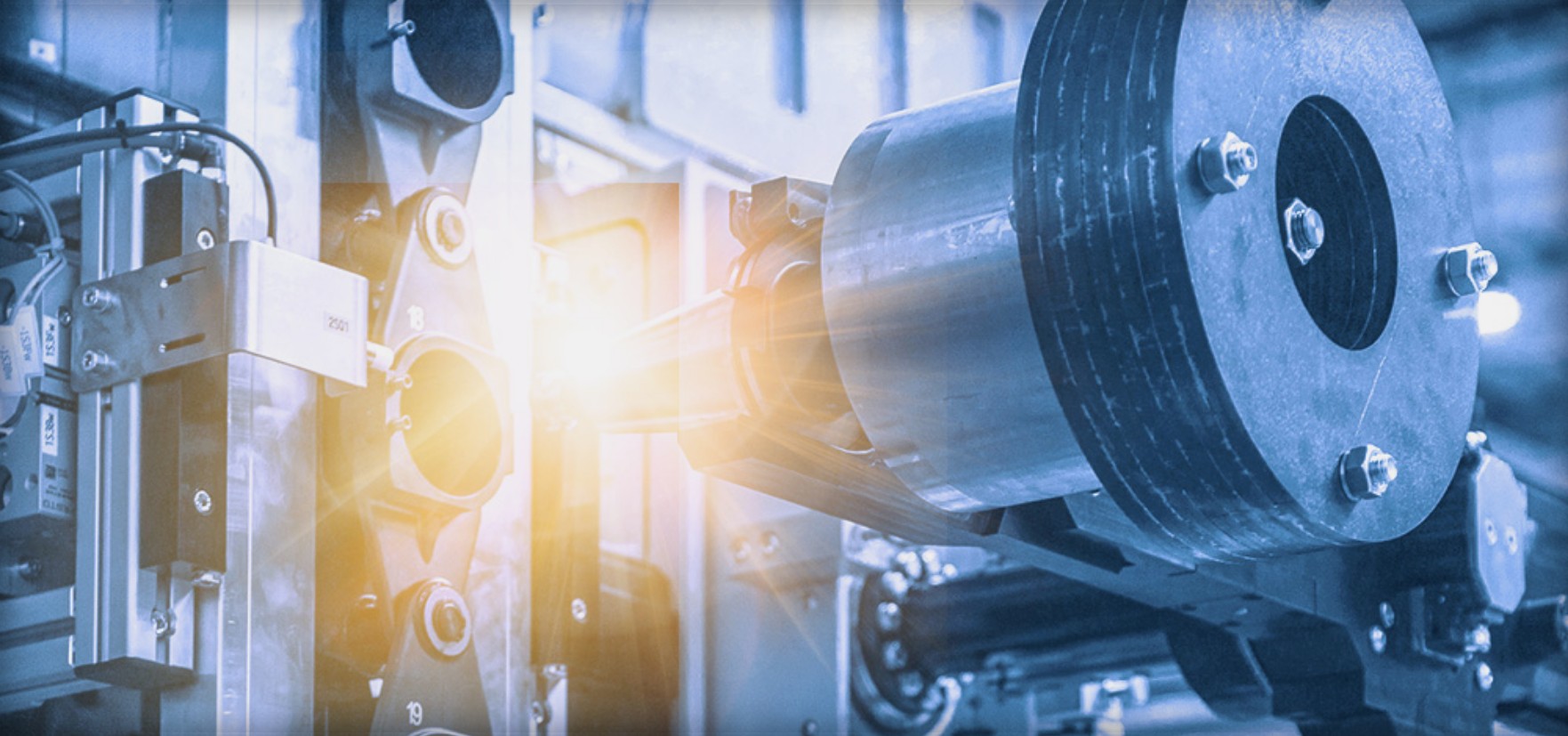

FROM THE INITIAL IDEA TO IMPLEMENTATION

We create all in one place

From idea to implementation

and functionality. For more than 70 years. Our success is based

on the professionalism and expertise of our specialized teams.

Last NEWS

AMPS PROJECT MEETING IN VÚTS

OECD DELEGATION AT VÚTS

FAMILY BUSINESS VÚTS IN A MAGAZINE

AIRCRAFT + AEROSPACE MAGAZINE

GENERAL MEETING OF SHAREHOLDERS

Robotics Opportunities Fair 2025

LECTURE ON INDUSTRIAL LASERS

SCHNEIDER ELECTRIC IN VUTS

VÚTS PART OF EMERGENCY SERVICES TRAINING

CIMT 2025 FAIR IN BEIJING

VUTS AT THE STYL AND KABO FAIR

ROBOT INTEGRATOR EVENT 2025

VÚTS IN THE MAGAZINE ELEKTROPRŮMYSL

TOGETHER WITH D. PABIŠKA AT DAKAR 2025

MERRY CHRISTMAS AND PF 2025

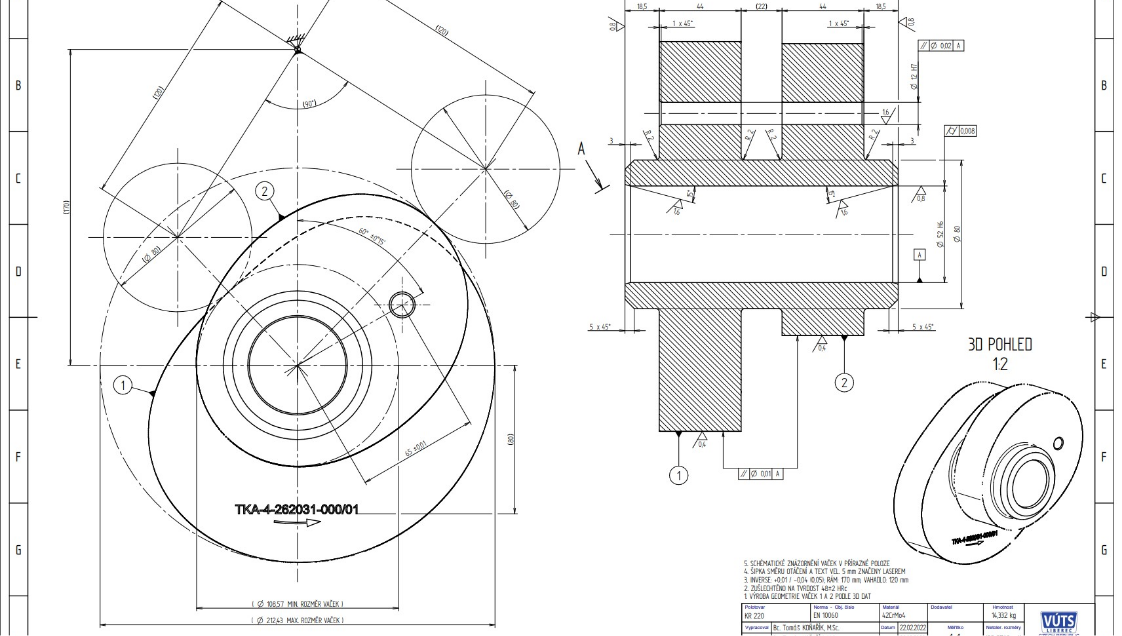

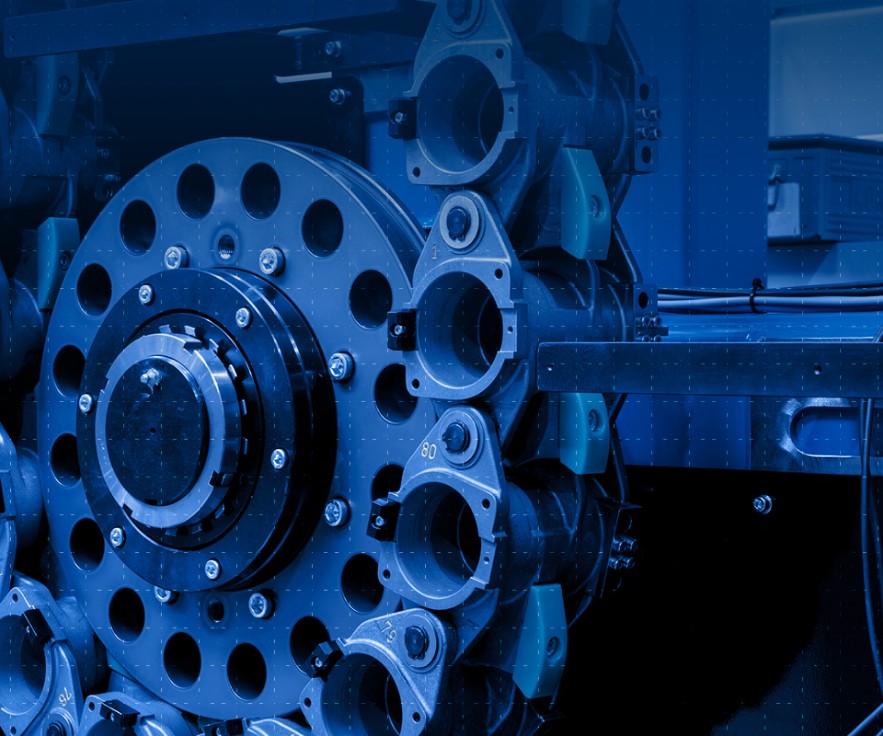

WE INCREASE YOUR POTENTIAL

We push forward a wide range of disciplines

and we refine the results of research and development into a functional model or prototype.

ReferenceS

Our partners are subjects from the both commercial and academic spheres.

1990-2025 © VÚTS a.s. - Všechna práva vyhrazena. | Cookies | Ochrana osobních údajů