Laser technology

We offer custom solutions in the field of machining, welding and laser heat treatment technology using the newest laser technology.

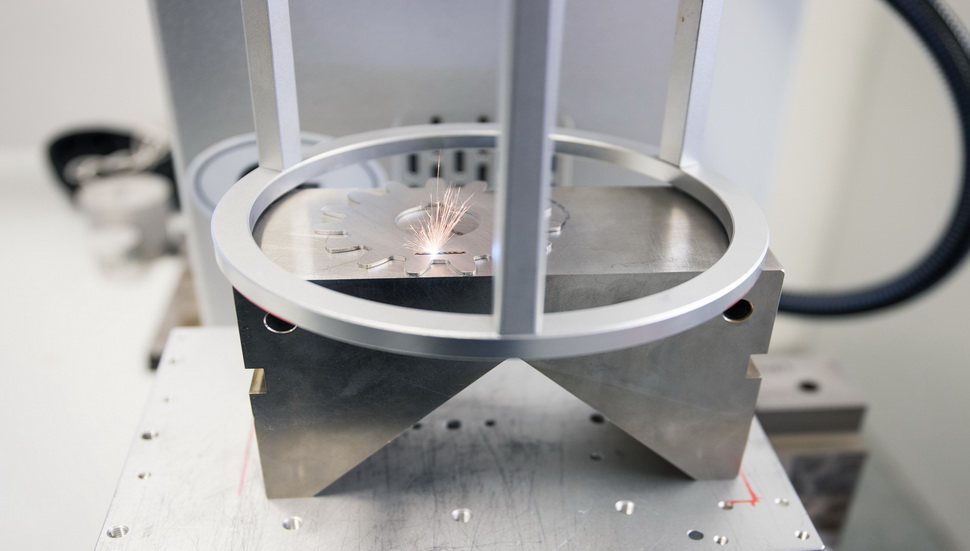

LASER HARDENING OF MOLDS

Laser hardening methods:

- Contour - with 1 spot of a width of 4, 8 or 16 mm

- Surface - using an overlapping method

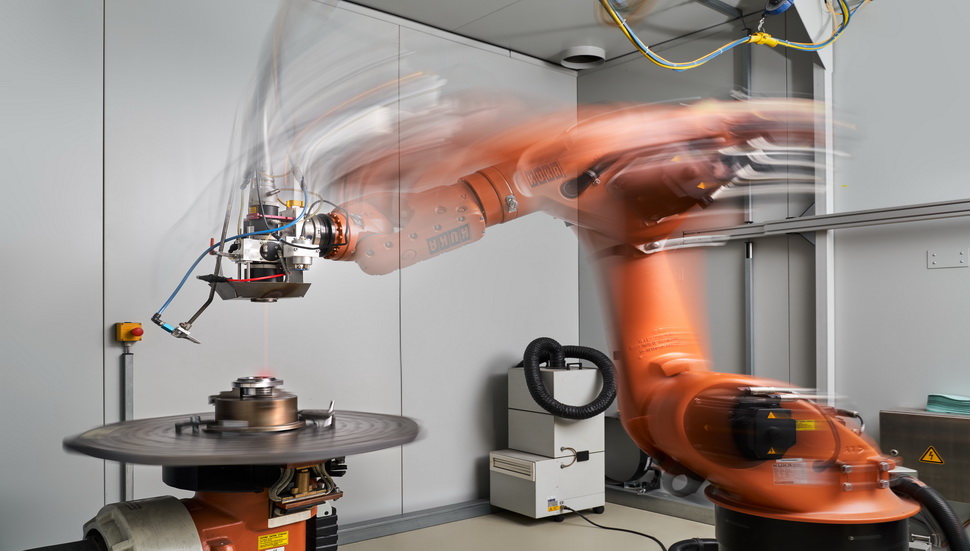

LASER HARDENING

Use:

- Refurbishing existing surfaces

- Increase the life of a part

- Creating new functional surfaces and coatings for pressing and cutting tools

- Increasing the resistance of highly stressed parts

laser cutting

We offer 2D cutting of structural steel, stainless steel and non-ferrous metals up to a thickness of 4 mm and a maximum size of 800 x 600 mm.

LASER WELDING

- Laser weldig of metals:

Efficient method of fastening metal parts without additional material. We offer both pulsed and continuous mode welding. It is possible to weld in a protective atmosphere of argon. - Laser welding of plastics:

Transparent laser welding of thermoplastic by non-contact joining method without additional material. The result is very precise gas-tight welds that are highly resistant to mechanical stress.

LASER ENGRAVING

Engraving of metal materials to a depth of tens of mm.

METALLOGRAPHIC LABORATORY

- Metallographic preparation of various types of specimens

- Microstructure evaluation - optical/electron microscopy

- Spectrometry (EDX)

- Measurement of hardness and microhardness (checking the hardness of parts

after hardening, checking the depth of hardening) - Possibilities of studying phase transformations in materials

1990-2025 © VÚTS a.s. - Všechna práva vyhrazena. | Cookies | Ochrana osobních údajů